About the Project

The WI-grown Kernza® Supply-chain Hub is a collaboration between Clean Wisconsin’s Natural Climate Solutions Initiative, Michael Fields Agricultural Institute, UW-Madison’s Picasso Research Group, UW-Madison Extension’s Emerging Crops Program, Rooster Milling and WI Kernza® growers, to unify WI Kernza® partners, align with regional Kernza® efforts,and to pilot a 100% WI-grown Kernza Farm-to-Fork and Farm-to-Glass supply chain development program to help scale this natural climate solution for WI Agriculture.

Transforming Wisconsin’s agriculture for the future

Wisconsin has set ambitious climate goals, but the state’s agricultural sector, which has seen a 23% rise in emissions since 2005, is not yet equipped to meet these targets. To succeed, Wisconsin’s farming practices must rapidly evolve to capture more carbon dioxide than they emit.

Why it’s important

Kernza® is a perennial intermediate wheatgrass developed by The Land Institute for both culinary grain and livestock forage uses. The formation of the Wisconsin Kernza® Supply Chain Hub was inspired in part by the challenges encountered by a prominent brewery in Milwaukee in trying to source Kernza® grain to make beer. The Kernza® purchased by the brewery was grown just 30-45 minutes from Milwaukee, yet had to be shipped over 1,000 miles to be aggregated in Minnesota, then to North Dakota to be cleaned and processed, and then back to Minnesota to coordinate delivery back to Milwaukee. This is both expensive and increases the carbon footprint which negates the carbon and economic benefits of locally grown crops.

While Kernza® is still a niche crop with many improvements that need to be made, the opportunity is ripe to start laying the groundwork for expanded adoption in Wisconsin. Commercializing new crops is a complex endeavor, but the promise of Kernza® to help create a more sustainable, resilient, and just agricultural system motivates us to do this work. The Wisconsin Kernza® Supply Chain Hub has already made considerable progress and we have only just begun.

What we’re doing

To begin addressing supply chain bottlenecks in Wisconsin, the Wisconsin Kernza® Supply Chain Hub has brought together key stakeholders, including growers, processors, and buyers, to identify major challenges they face and coordinate activities aimed at overcoming these obstacles. This pilot project is facilitating sourcing, processing, and purchasing between WI growers and WI businesses, and is using the experience(s) and feedback to better understand the needs and constraints along the WI-grown Kernza® supply chain, address the bottlenecks, and refine the services and capacity of Rooster Milling to meet the needs of WI businesses and consumers. Our ultimate goal with the project is to facilitate the production of WI-grown Kernza® products (i.e. a beer, spirit, and/or baked product) to demonstrate that when grown and processed in the “right” quantities and to the “right” specifications, that WI-grown Kernza® has enough market interest and value to be worth further investment into the supply-chain infrastructure necessary to scale WI-grown Kernza®.

Project Milestones

January

- Rooster Milling becomes first SE WI certified cleaning and processing facility equipped to handle small-grain Kernza® at a commercial scale

March – May

- Ten new Kernza® growers and five research stations — comprising 96.2 acres across 12 counties in Wisconsin — were invited to participate

- Creation of a WI Kernza® Supply/Demand Inventory to track acreage, management practices, certifications, predicted and actual yields

June – July

- The Hub helped organize several farmer field days to expand awareness of Kernza® and its environmental benefits

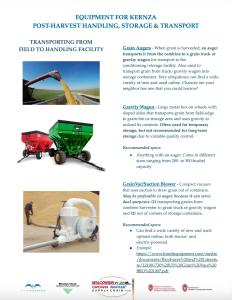

- Post-harvest Guidelines & Recommendations were developed to fill the gap in information and resources

- Prospective end-buyer Outreach provided beer tasting and whole-grain samples to prospective brewers in Wisconsin

August – October

- First-year harvests for existing growers were coordinated, new growers were recruited and seed for planting was sourced; several new 2025 WI Kernza® growers joined the Hub

- An estimated 4,000 pounds of Kernza® were harvested — enough to brew 100-300 barrels of beer, using 10-30% Kernza®

- Post-harvest Guidelines & Recommendations were shared with WI growers and regional Kernza® advocates

November – December

- The Hub hosted two WI Kernza® grower roundtable discussions to learn more about needs for the 2025 season, historical Kernza® pricing and implications for end-buyers

- The Hub hosted a WI Kernza® Supply Chain Field Day at Rooster Milling to bring WI growers, prospective buyers (including breweries, distilleries, bakers and chefs) together to taste products, learn about Kernza® end-uses and more

WI Kernza Grower Resources

The resources below have been compiled by Clean Wisconsin and other partner groups involved in the WI-grown Kernza® Supply Chain Hub pilot project.

Click the “Read More” button beneath each image to access a downloadable version of each file.

Stay tuned for more resources in the future!

WI-grown Kernza® Technical Service Providers

Planting, Establishment & Harvest

Kernza® Grower Guide

Kernza® Identity Preserved Program Guidelines

Post-harvest Guidelines & Recommendations

Kernza® post-harvest pathways flowchart

AURI’s Kernza® Cleaning & Dehulling flowchart

Equipment Needs & Recommendations

Kernza®

Handling

Requirements

WI Kernza® Grower

Quality Testing

Requirements

University of MN’s Forever Green Initiative Kernza® Seed & Grain Testing Protocol

Selling and Shipping WI-grown Kernza®

Sample contract_Kernza® Grain Buying Agreement

LTL (Less-Than-Truckload) Freight Shipping

Learn More

The NCS Roadmap to Net-Zero for WI Agriculture Project is a two-year collaboration between Clean Wisconsin, Michael Fields Agricultural Institute, Savanna Institute and UW–Grassland 2.0, and is structured as one large initiative with three smaller pilot projects, including the WI-grown Kernza® Supply Chain Hub. This work is made possible thanks to the generous support of The Daybreak Fund.